Employee Spotlight: Kate McHardy – Head of Sales

Ionoptika is very proud of its skilled and dedicated staff, who together with our loyal users make up our global community. Our new regular post will shine the spotlight on some of the people who make up Ionoptika!

This week’s spotlight focuses on Ionoptika’s Head of Sales, Kate McHardy. Kate joined Ionoptika in 2019, so is still a relative newcomer to the team. We asked her what she makes of life at Ionoptika so far!

How long have you worked at Ionoptika and what career path brought you to us?

I joined Ionoptika in April 2019, having spent the previous 17 years working in a similar role at a company called Oxford Cryosystems, specialising in cooling devices and cryostats, mainly for X-ray crystallography applications. Like Ionoptika, Oxford Cryosystems was a small yet specialist research and engineering company. I loved my time there and still have many friends at the company, but after 17 years, felt it was time for a change!

What do you enjoy most about working at Ionoptika?

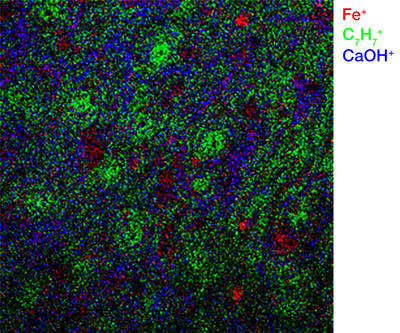

One of the most exciting things about Ionoptika for me is the important applications that our instruments can be used for. Our J105 SIMS, for example, has been used as a research tool for understanding skin cancer and breast cancer; or demonstrating the presence of cocaine metabolites in fingerprints. It is quite inspiring to meet the researchers working in such important areas, and to feel that the instruments we develop and offer can add such value to these important fields.

I have been involved in international sales and marketing for many years now, and one of my favourite parts of the role is getting out to see customers at their labs to appreciate the work they are doing and attending conferences and exhibitions. So this year, the restrictions on international travel have been rather frustrating!

We have a very talented team at Ionoptika, working on some really diverse R&D projects, so there is no shortage of work for the Sales & Marketing team, as we work out how to commercialise these new developments.

What would a typical day look like for you working in Sales?

In any other year, our Sales & Marketing team attend a lot of conferences and exhibitions. So a typical day might involve preparing for those coming up, attending the meetings, both as a delegate and exhibitor, meeting existing and potential new customers, or following up on discussions we have previously had. This year, this has been replaced with a lot of planning for the future and Zoom meetings!

However, one of the great things about working for Ionoptika, is that no day is the same; and this year, working from home, that’s saying a lot! We have a very talented team at Ionoptika, working on some really diverse R&D projects, so there is no shortage of work for the Sales & Marketing team, as we work out how to commercialise these new developments.

What has been your best memory or achievement in your time at Ionoptika?

In the 18 months of my time with Ionoptika, unfortunately half of that time has been during the Covid-19 pandemic! However my first 9 months with the company was extremely busy and I was lucky enough to attend the SIMS 22 conference in Kyoto, which really allowed me to meet a lot of our customers and collaborators.

What do you enjoy doing in your spare time?

I have only lived on the South Coast for 18 months now, so I am really enjoying getting out walking and exploring the beautiful local area. I do have a passion for travel, but this year, that has necessarily had to be a bit closer to home!

Have you been doing anything interesting/different/new to cope with the lockdown?

Lots of gardening during the summer and lots of walking now!

What are you looking forward to most once the lockdown is over?

At the moment, our region’s restrictions mean we can’t meet other households, so I am most looking forward to meeting up with friends again and being a bit more social. And overseas travel of course, I certainly miss that!

Interested in becoming part of our team? Visit our Careers page.

Ionoptika 2020

Ionoptika 2020

Ionoptika 2020

Ionoptika 2020

Ionoptika 2020

Ionoptika 2020

Ionoptika 2020

Ionoptika 2020

Ionoptika Ltd 2020

Ionoptika Ltd 2020