ToF-SIMS Analysis on Insulating Samples

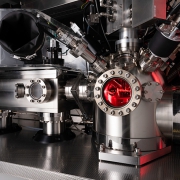

Performing ToF-SIMS analysis on insulating samples can be particularly challenging. Surface charge can impact the accuracy of the results, or in the worst cases prevent any results being obtained. Thanks to its unique ToF design, the J105 SIMS is capable of imaging highly insulating samples without loss of signal or performance.

The Problem

Insulating samples provide a particular challenge for the ToF-SIMS user. A charged beam of particles impinging a surface necessarily produce a surface charge, both by emission of secondary electrons and by transfer of charge to that surface. For a metallic sample this charge is easily dissipated into the surrounding bulk, however this is not the case for insulating materials where there are no free electrons to neutralize the charge. The result is a build up of surface charge that can have a number of deleterious effects on a ToF-SIMS experiment.

For instruments where the time reference is determined by the primary beam pulse, regions of surface charge can affect the flight time of ions ejected from the surface, thereby negatively impacting on the mass-accuracy of the experiment. This effect is particularly pronounced around regions of topography where field strength is enhanced – in the worst case this leads to highly distorted fields preventing ions from ever reaching the detector. The most prominent effect of surface charge, however, is the suppression of secondary ion signals due to field suppression and/or neutralization prior to extraction.

The Solution

Thanks to its unique ToF design, the J105 SIMS is capable of imaging highly insulating samples without loss of signal or performance.

ToF Design

As the J105 does not rely on a pulsed primary beam as a time reference, temporal aberration in the extraction gap, caused by sample charging or other effects, has no impact on the mass accuracy. This enables a large extraction gap and a low extraction field, which in turn mean the extraction optics can accept ions leaving the sample up to very large angles from the normal, increasing transmission. The overall result is consistent performance across the entire sample, even those areas with lots of topography.

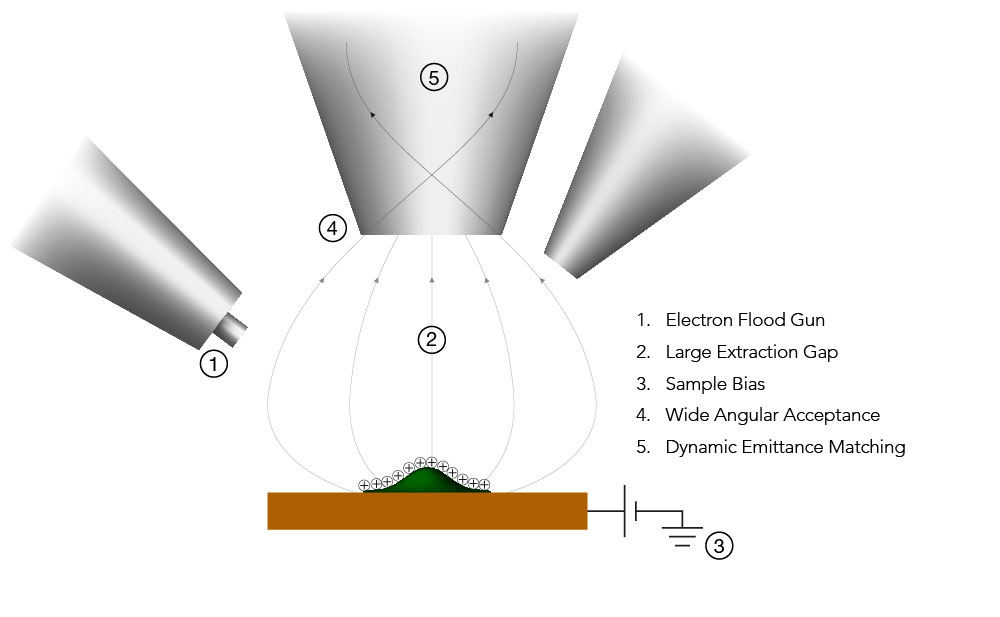

Schematic illustration of the various means by which the J105 SIMS can compensate or accommodate charging samples.

Charge Compensation

Charge compensation/neutralization may be used to alter the effects of surface charge and improve signal on charging samples; this can be achieved by sample biasing and/or low-energy electron bombardment. In sample biasing, the sample stage is biased up to ± 100 V to compensate for the field created by the surface charge. This requires that the bias voltage is able to reach the sample surface, and so may not be effective on thicker samples or in situations where conductive tracks are prohibited.

Alternatively, pulses of low-energy electrons may be interlaced between the primary beam, in a pseudo-DC mode, to directly neutralize the charge on the surface. This has advantages in that the electrons are naturally drawn to localized pockets of charge, providing a “self-limiting neutralization” mechanism. One must be careful however, as even low-energy electron beams may result in damage to fragile organic structures. Generally speaking, in most situations, it is best to use a combination of both techniques, experimenting to find the correct balance for each individual sample.

Insulating Samples

Sodium Citrate Crystal

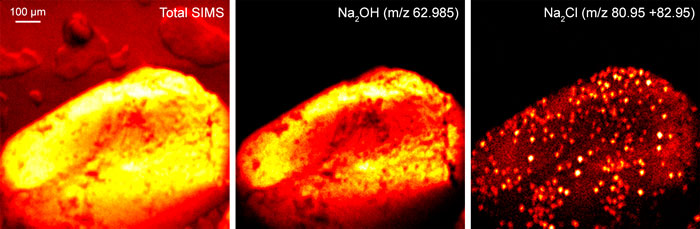

The figure below shows SIMS images of a single sodium citrate crystal on a substrate of double-sided tape – both highly insulating materials. Using a combination of sample bias and electron flood gun to neutralize surface charge, good signal levels are obtained from all areas without loss of mass accuracy or mass resolution, despite the highly topographic surface, enabling the identification of small micro crystals of NaCl within the sample.

SIMS images of a single sodium citrate crystal on double-sided tape, obtained with a 40 kV C60+ beam, showing (left) total secondary ion image, (middle) Na2OH (m/z 62.985), and (right) Na2Cl (m/z 80.95 + 82.95).

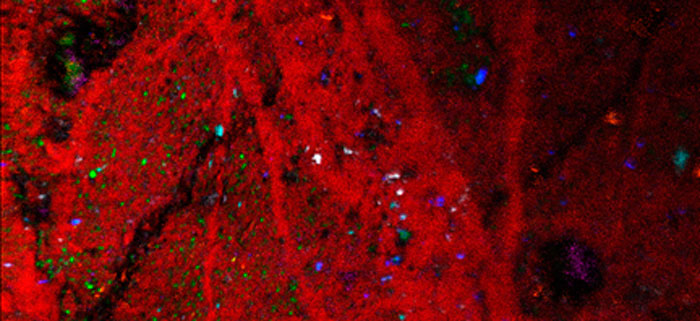

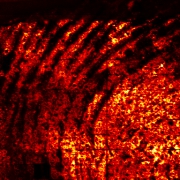

Polished Rock Surface

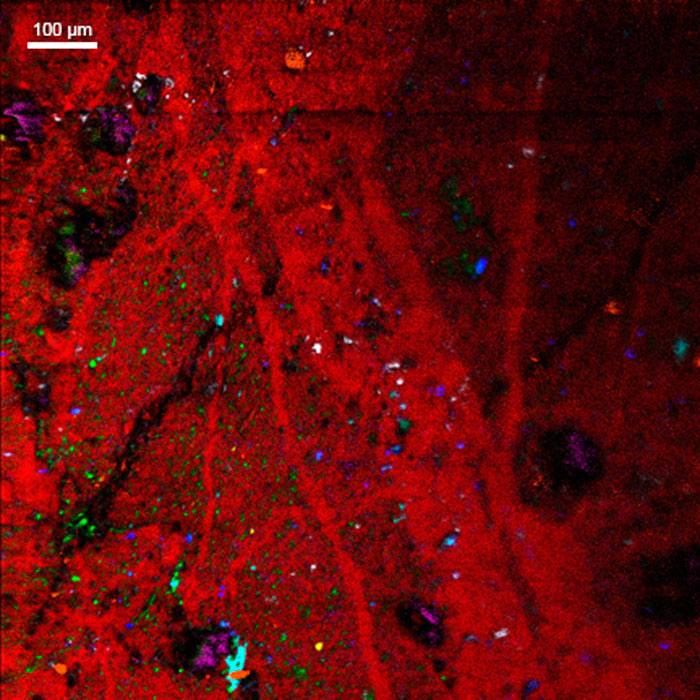

The second example shows a SIMS overlay image of a polished rock surface. The image is a 1 x 1 mm area, taken at 1024 x 1024 pixels using a 40 kV C60+ beam. A combination of electron flood gun, and sample bias was used in this instance, with +60 V applied to the stage in order to compensate for the effects of charging. A number of elements and minerals are identified in the image, including K, Ca, SiOH, Mn, Fe, and TiO.

SIMS overlay image of a polished rock surface, imaged with a 40 kV C60+ beam. A combination of a low-energy electron flood gun and sample biasing was used to optimise imaging conditions for this insulating sample. Elements and minerals visible include: K (green), Ca (yellow), SiOH (red), Mn (cyan), Fe (white), and TiO (blue). Data courtesy of Dan Graham & Tina Angerer.

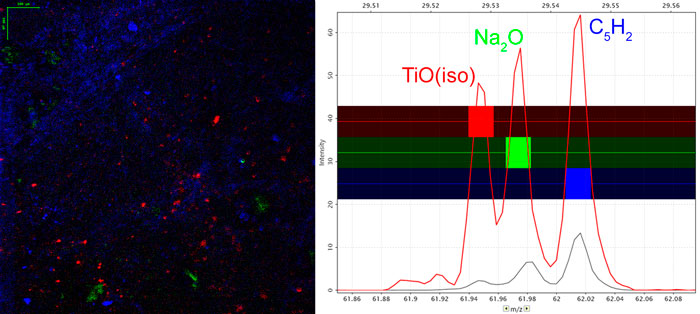

Mass Accuracy

Despite the charging nature of this sample, consistent mass accuracy is maintained across the data set. This is illustrated in the figure below, where three peaks, TiO, Na2O, and C5H2 respectively, are identified with sub 5 ppm accuracy. As evidenced by the overlay image accompanying the spectrum, all three peaks are spatially distributed throughout the sample. Spatial resolution, mass resolution, and mass accuracy all combine to make peak identification a routine procedure, even on challenging samples such as this.

SIMS overlay image & spectrum of polished rock surface. Even on highly insulating samples such as this, high mass accuracy (<5 ppm) is maintained at all points, enabling identification of numerous mineral fragments and organic species. Data courtesy of Dan Graham & Tina Angerer.

Conclusions

Real-world samples – where sample charging and topography are unavoidable – have always posed a challenge to reliable ToF-SIMS analysis. Now, through innovations in instrument design and engineering on the J105 SIMS, analysis of such samples is becoming routine, giving you more time to focus on solving the important problems. If you would like more information, or would like to speak to a member of our team, please get in touch via our Contact page.

Ionoptika 2020

Ionoptika 2020  Ionoptika

Ionoptika  Ionoptika Ltd

Ionoptika Ltd  Ionoptika Ltd

Ionoptika Ltd